Grand Prix 5000

The rolling properties of the rubber compound of a tire are primarily determined by three interacting factors – stiction [grip], rolling resistance and mileage [longevity] . The dilemma: If you improve any of these factors it can have a detrimental effect on at least one of the others. A tire with maximum grip wears quicker and rolls more slowly. If you then make a tire roll faster and more durable, grip, in turn, is reduced.

With our Black Chili compound, a tread compound which is always based on the latest knowledge of polymers and raw material research, we have supplied the cycling industry with an enduring solution. Depending on the application of a tire, we adjust the compound formulation for the specific discipline – for road or mountain biking, time trialling or downhill racing.

How does that work? For Black Chili we refine special synthetic rubbers with proven natural rubber to high-performance tread mixtures. To these mixtures we then add soot particles, which in turn are optimised in shape and surface properties.

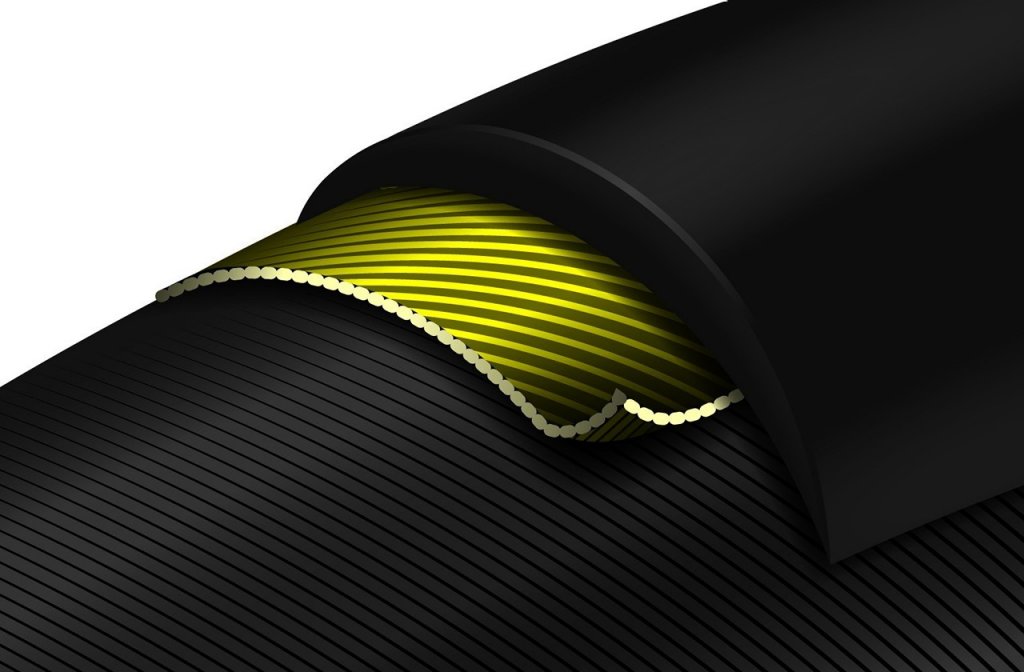

Vectran™ is spun from liquid crystal-polymer. This way a thermoplastic, multiple-thread yarn is created. As a comparison: This partially crystalline fabric is more cut-resistant than aramide and its tensile strength is five times higher than that of steel. A Vectran™ Breaker is lighter, more flexible and effective against cuts than a comparable nylon breaker. Without effecting rolling resistance.